Veneered Wood and How it Compares to Solid Wood

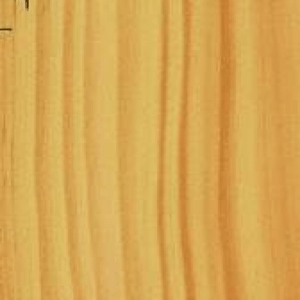

Veneered wood consists of a thin strip of wood which is glued or bonded to cheaper, solid core panels. These panels may consist of plywood, particle board or MDF, but the wood strips on the outside can be made from a variety of natural woods.

Therefore furniture made from veneered wood is generally cheaper then items made from solid wood, yet has the same positive visual impact.

How is Veneered Wood Made?

Veneered wood is produced by slicing very thin layers from a log, in comparison to solid wood which is acquired by sawing. The method used for solid wood will create more waste from the log, the thin strip methodology of veneered wood instead maximising the output from the log.

Veneered wood is produced by slicing very thin layers from a log, in comparison to solid wood which is acquired by sawing. The method used for solid wood will create more waste from the log, the thin strip methodology of veneered wood instead maximising the output from the log.

Advantages of Veneered Wood

- The wood veneer sheets add stability and durability by protecting the veneered plywood, particle board or MDF core, making them less prone to warping then solid wood

- By using veneered wood you obtain the aesthetics of natural solid wood but at more affordable prices, allowing you to improve the look of your home on a more manageable budget.

- Veneered wood offers a more uniform finish, making it easier to source similar products.

- Veneered wood is a recyclable product which can be used to make more particle board and MDF.

Do I Still Get Quality With Veneered Wood?

As with solid wood items the quality of veneered wood depends on the quality of the natural wood used and also the quality of the substrate, including veneered plywood, which makes up the core. High end designers use veneered wood in their modern day design as it is functional, pleasing on the eye and provides a wood structure which offers a unique finish.

Is it Completely Natural?

The thin outer strips of wood and the core it is bonded to is natural and a good environmental choice. However it does require glue to bond together which can contain formaldehyde, although non-toxic glue alternatives are available on the market today.

Manufacturing Process of Veneered Wood

Every household and every office own a piece of furniture, and it depends on its use. Veneer refers to many thin-paper layers of wood that are fused under heat. Veneered plywood is the finest piece of veneered wood. There are ten steps in the process of manufacturing wood veneers.

- The Log Yard

The logs are kept in a humid environment from the forest to avoid degradation and soften the fibres.

- Bark Removal

Removing the bark from a tree log isn’t easy; it takes precision and patience to acquire the evenness.

- Log Soaking

The tree logs are fed to steamers and immersed at temperatures between 80 and 100 degrees Celsius for a maximum period of 72 hours to soften the fibres to achieve uniform slicing.

- Log Cutting

The technique used to acquire veneer determines where the cut will be since there is a barcode on the already identified logs.

- Peeling

The veneer logs of the same tree should be tested and added carefully at every stage. Separate tags that correspond to the log barcodes are carefully verified and attached. The veneer sheets are sliced from the tree logs in this step, and there are several different methods to do this;

- Half-Round Slicing

- Rift Slicing

- Quarter Slicing

- Rotary Cut

- Flat Slicing

- Drying

The sheets remain in natural order since when they emerge, all parts of the log are kept together. They are then uniformly dried at 320° C and long enough for 8-12% of moisture to be preserved.

- Quality Affirmation

Identifications are subject to various verification. Inspections are made to each log by an expert who makes sure that customers receive quality veneers.

- Clipping

The angle and perfection of the cut determine the quality of veneer panels produced. A clipper is used to acquire sheets that are even in length and width.

- Splicing

The veneer sheets are assembled in this stage to create a match. A stable and consistent match is determined by the amount of pressure exerted. There are a large variety of veneer matching;

- Balance match

- Random match

- Reverse Slip match

- End match

- Slip match

- Packing

Once measured, the veneer sheets are packed and labelled with the length and width and are ready for transportation.

Buying Veneered Wood

Theo’s Timber Ltd are timber merchants in Manchester who offer a broad range of timber products, including veneered wood, across the North West. You can find our range of veneered wood at Theo’s Timber to view samples of the different cuts available. With a breadth of experience, we can advise you and provide the right veneered wood solutions for your home, allowing you to experience the beauty of natural wood products at more affordable prices.