Description

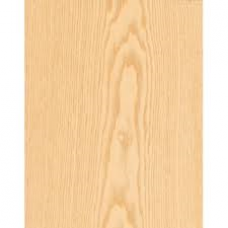

Discover the endless designs of oak veneered MDF and elevate your timber projects with this exceptional alternative to solid wood. Not only does it offer cost-effectiveness, but its beauty and durability are second to none. Get ready to be captivated by the versatility and elegance of oak veneered MDF, as we delve into its irresistible features and why Theos Timber Limited is your ultimate destination for premium oak veneered boards.

Benefits and Versatility of Oak Veneered MDF

Unmatched Durability for a Budget-Friendly Investment

Say goodbye to compromise and hello to long-lasting brilliance. Oak veneered MDF provides an affordable solution without sacrificing quality or style. Unleash your creativity and bring your design visions to life, all while staying within your budget. At Theos Timber Limited, we take pride in offering oak veneered sheets that surpass industry standards, ensuring the utmost integrity of your projects.

Tailor-Made Features for Your Construction Desires

Our veneered sheets are meticulously crafted by bonding standard MDF with real wood fibres, held together by synthetic resin. The result? A stunning uniform oak wood grain that emulates the charm of veneered plywood. With its smooth surface, these boards are not only perfect for decorative applications but also versatile enough to cater to a wide array of needs.

From office furniture to cabinets and shelves, the sturdy nature of oak veneered sheets guarantees exceptional performance in every setting. Bid farewell to concerns about warping, as the MDF core ensures impeccable resistance, making these sheets ideal for elegant wall panelling as well.

Unrivalled Quality and Dependability from Theos Timber Limited

Premium Oak Veneered Boards

When it comes to oak veneered boards, Theos Timber Limited is your unwavering source of unparalleled quality. We go above and beyond to offer only the finest oak veneered sheets that will leave you in awe. Transform your projects with confidence as our products can be easily varnished, oiled, or stained, enabling you to achieve the rich and luxurious appearance of solid wood you desire.

Seamless Customisation and Hassle-Free Application

Embrace the ease and convenience of working with oak veneered MDF, whether you’re a seasoned professional or an avid DIY enthusiast. Cutting through this exceptional material is effortless, making your projects a breeze to accomplish. Moreover, our boards are designed to minimise wastage, allowing you to customise and fit them precisely to your needs. For that added touch of refinement, utilise iron strips to elegantly finish the thin veneer edges.

A World of Possibilities with Oak Veneered Sheets

From mesmerising fire surrounds to breathtaking kitchen cabinets, the possibilities are limitless with oak veneered sheets from Theos Timber Limited. Our FSC-certified products not only deliver stunning results but also contribute to responsible sourcing. By choosing our oak veneered MDF options, you’re making an environmentally conscious decision while creating structures that exude elegance and style.

Begin Your Construction Project Today

Visit our extensive range of oak veneered sheets and embark on a journey of exceptional design and limitless potential. Let Theos Timber Limited be your trusted supplier of reputable highly quality materials. Elevate your craftsmanship and enhance your projects with the use of oak veneered MDF today.

Reviews

There are no reviews yet.