Veneered MDF

Although wood is an excellent option for durable and stylish builds, it’s not the cheapest material for most projects, particularly DIY. However, just because you don’t have the budget for natural wood doesn’t mean you can’t have a long-lasting and elegant installation. Veneered MDF is the best alternative to solid wood. You can use veneered MDF sheets for a host of applications, including furniture manufacturing, cabinetmaking and wall panelling.

What is Veneered MDF?

Veneered MDF (medium density fibreboards) consist of high-grade wood veneers bonded to standard MDF. Under high pressure, wood fibres are combined using resin to the desired thickness. Both sides of the sheet have laminate veneers, measuring 0.55 mm each. The resulting grain resembles natural wood, which is part of the appeal of this material. An edging strip can be added to a veneered board for the perfect finish. Theos Timber supplies superior standard veneer MDF sheets in a range of finishes. Our high-quality veneer MDF is manufactured from top-grade wood fibres, guaranteeing a long lifespan for your constructions.

Benefits of Veneered MDF

Versatility is a big selling point of veneered MDF sheets. The boards are strong enough to be used in various applications. Additionally, they are easy to stain and paint, allowing customisation to suit any aesthetic requirements. You can use them for office furniture, dining furniture, shelving, panellings and fire surrounds, among others.

The fibres in the MDF core are bonded using resin, making them more stable than solid wood. This quality gives veneered sheets better resistance against temperature fluctuations, preventing warping.

A Veneered MDF board is lightweight, making cutting to different sizes uncomplicated. You can cut and drill the sheets to match any requirements, enabling you to build furniture or other pieces without too much wastage. Also, the boards allow for the easy construction of custom builds.

The fibres used in veneered boards are recycled materials, such as sawdust and wood pallets. So, you get to build with eco-friendly raw materials. Theos Timber sells FSC-certified products.

Veneer MDF sheets are simple to work with because they sand, mark and drill easily. Therefore, they are suitable for DIY projects, particularly for an amateur. You can use an electric saw, handsaw or router to cut boards. Screws, nails and other fastenings work effortlessly with the sheets.

If you have any other questions in regards to our MDF veneer sheets and panels, please contact us and we’d be happy to help. We only offer the best quality sustainable products and source our materials from the finest suppliers. We also have a wide range of other MDF products available on our website such as oak veneer & flexible MDF, so please take a look around.

Showing 1–12 of 17 results

-

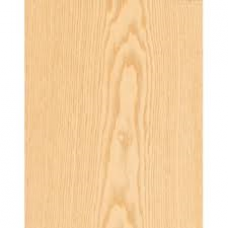

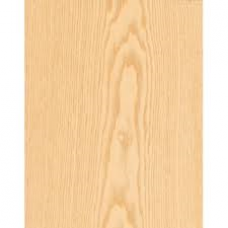

Ash Veneered MDF (2440 x 1220mm)

Read more -

Ash Veneered MDF (3050 x 1220mm)

Read more -

Cherry Veneered MDF (3050 x 1220mm)

Read more -

Cherry Veneered MDF (2440 x 1220mm)

Read more -

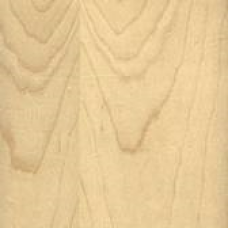

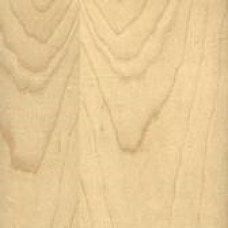

Maple Veneered MDF (2440 x 1220mm)

Read more -

Maple Veneered MDF (3050 x 1220mm)

Read more -

Oak Veneered MDF (2440 x 1220mm)

Read more -

Oak Veneered MDF (3050 x 1220mm)

Read more -

Pine Veneered MDF (2440 x 1220mm)

Read more -

Pine Veneered MDF (3050 x 1220mm)

Read more -

Quarter Cut Sapelle MDF (2440 x 1220mm)

Read more -

Steamed Beech MDF (2440 x 1220mm)

Read more

Showing 1–12 of 17 results